Electric linear actuators are steadily gaining ground in MOH machine design applications. Where they could once efficiently replace single hydraulic or pneumatic cylinders in simple, end-to-end motion applications using up to 100 watts of power, today, they can perform complex motion profiles drawing power up to 400 watts. Part of this new functionality stems from embedding microprocessors into the design, thus creating "smart actuators."

Designing with smart actuators

Smart actuator applications could be as simple as low-level power switching or as sophisticated as implementing a control deck across a CAN bus network. Having a microprocessor in the actuator enables access to functionality and data that might otherwise have required incorporating external components. Before a smart actuator starts to move, it checks the environment to be sure it is safe for the user and the application. Once it starts, it measures its position along the stroke. Collecting this data without adding external sensors and other equipment also reduces the number of components you need and simplifies installation.

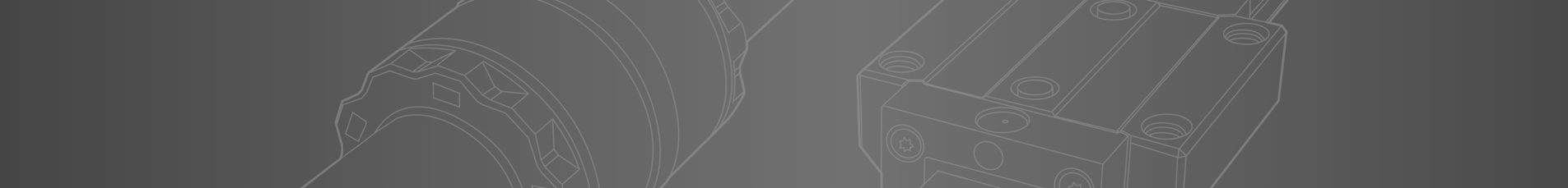

Figure 1. Embedded electronics synchronize multiple smart actuators to control storage bin doors opening and closing on this grain harvester.

Smart actuation is all about moving toward advanced control, more complex movements and ease of installation. If you have an application in which you want to move several actuators at the same time, you can accomplish that with simple cabling, completing movements and movement profiles independently. (Figure 1)

Self-driving agriculture equipment is a good example of a smart actuator application. Some grain harvesters, grape harvesters and farm tractors, for example. are already operating autonomously. This makes it critically important for actuators to control stroke and force on their own. By replacing an operator who might otherwise control operation from visual clues, a system running autonomously must rely on electronic feedback. Most smart actuators have built-in fieldbus capability to provide this feedback. Some, for example, have CANopen® masters so you can connect to a vehicle control directly without drivers or other components needed to access operating data. The vehicle's built-in logic manipulates speed, force and position from the master control unit and provides precise control of the actuator and knowledge of its position at every point of the stroke.

Advantages of electric actuators over hydraulic and pneumatic

The ease with which electric actuators control stroke, speed, position and force is certainly a major advantage of over hydraulic and pneumatic systems, but there are many others.

Energy efficiency is another important one. In traditional MOH applications, the hydraulic or pneumatic system must run all the time. Electric actuators, in contrast, are power on demand, consuming power only when there is a movement and without parasitic power loss.

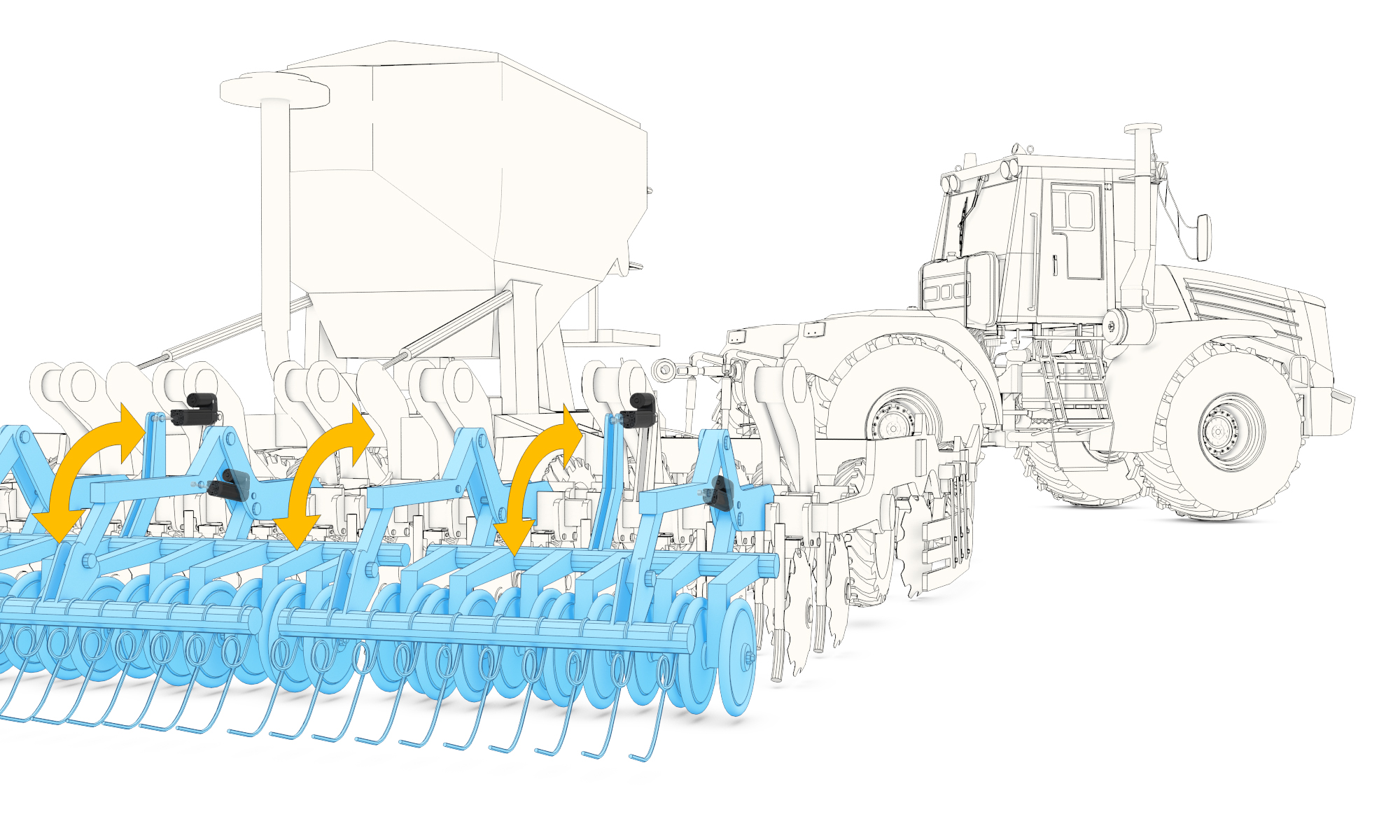

Electric actuators are also much easier to install. You simply mount them, connect power and signal cables, and you are done. Electric actuators are virtually maintenance-free. There is no oil to change or cleanup when it leaks. This makes electric actuators much safer for food-related applications such as the agricultural harvesters mentioned earlier. (Figure 2)

Figure 2. Because they use no hazardous oils, electric actuators are often preferred for food-related MOH applications, such as this seed planter.

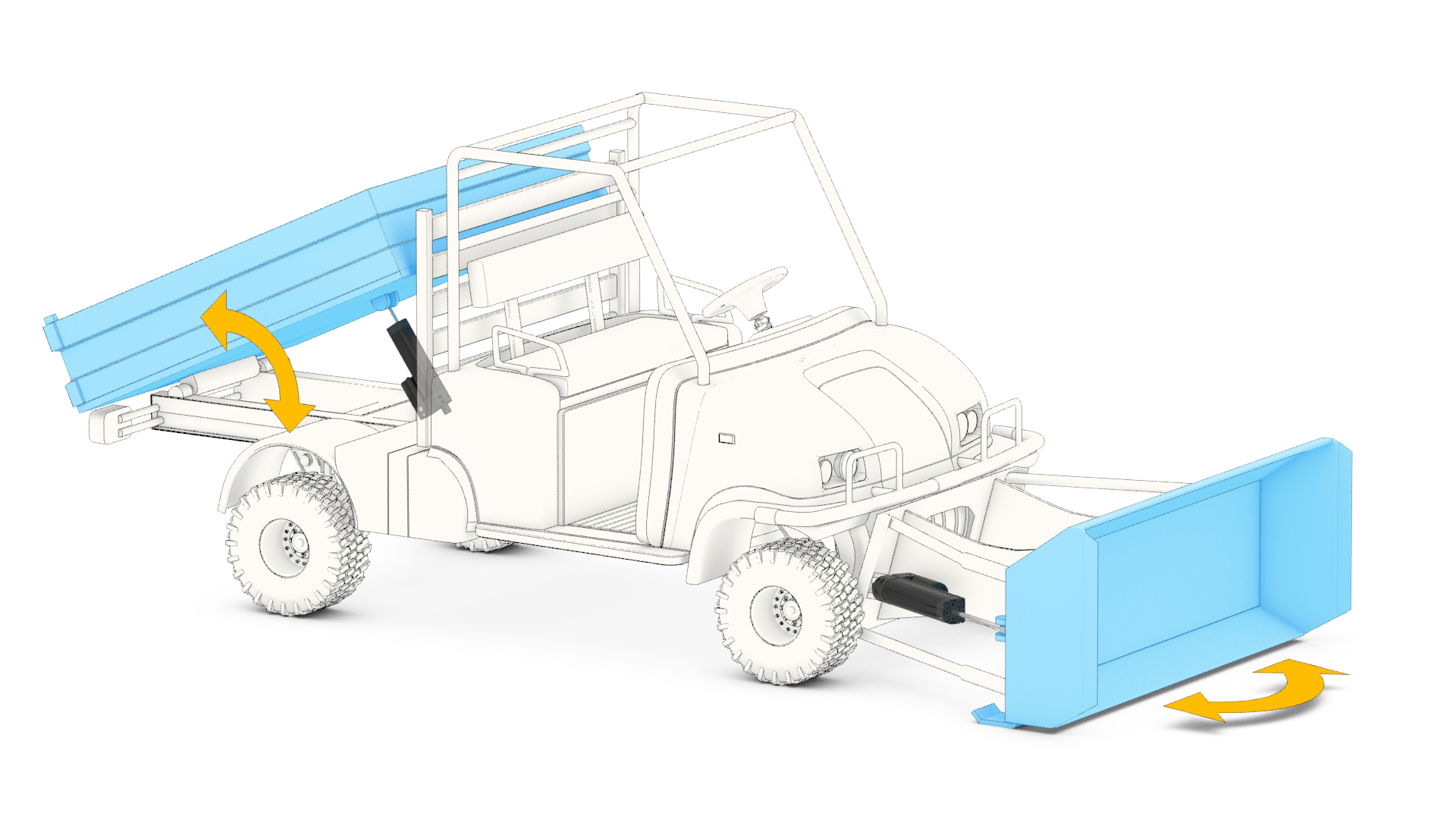

As such, electric actuators are evolving to perform tasks that were once the sole domain of fluid technologies. Electric actuators can already handle loads up to 16K Newtons. Another traditional limitation of electric actuators has been in shock load handling, but even this is being addressed to some extent by hybrid electro-hydraulic actuators such as the Thomson H-Track, which combines shock handing comparable to hydraulic cylinders with the intelligence and compactness of electric actuators. (Figure 3)

Figure 3. Hybrid electro-hydraulic linear actuators can perform some tasks that were once the sole domain of fluid technologies. Their ability to withstand shock loading for applicationssuch as this utility vehicle makes them ideal solutions for the MOH market.

The next frontier

As electric actuators advance, the number of off-the-shelf options is also growing. Probably the biggest challenge is identifying the existing and new areas where intelligent actuation brings value and mapping them to the wide range of available options. Once people get used to designing with electric actuators, they find possibilities everywhere. It could provide a safety benefit. It could lower the cost. It could be a way to add efficiency to a machine. There are also ergonomic benefits, such as automating a tedious task or adding more precision or repeatability.

As new motion control application needs continue to evolve, the intelligence, compactness and flexibility of electric actuators will give them an advantage in overcoming obstacles and leveraging new opportunities.